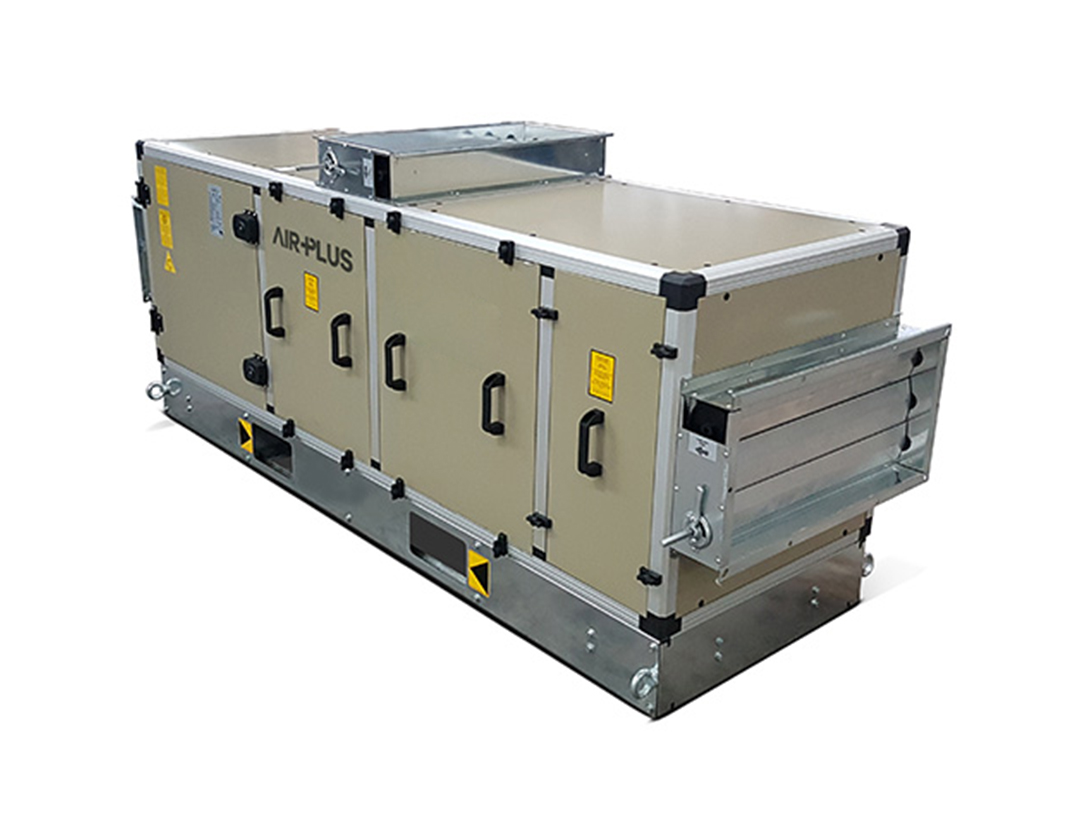

The carcass of our cell fans is manufactured from natural anodized aluminum profile and plastic corner elements. Cell panels are optionally 25 mm or 42 mm thick, the outer wall is electrostatic powder painted and the inner wall is made of galvanized sheet. It is indispensable for central ventilation applications thanks to its high efficiency and energy saving rock wool filled panels, modern carcass structure, static and dynamic balanced, silent, efficient double suction radial fans or plug fans according to customer request. Our electric motors are 380V-50Hz as standard.

The fan-motor assembly used in our cellular ventilators is on a vibration-damped chassis and power transmission is provided by a belt-pulley device. Thanks to this system, fan speeds can be adjusted as desired and optimum flow and pressure settings are realized.

All double wall panels are mounted to the aluminum frame with screws. As standard, service and intervention covers are double-walled rigid hinged without gaps, and the air handling unit lock, which does not protrude inside the cell with a compression feature that does not allow air leakage, is in a double-walled rigid structure so that the covers do not rub against the carcass frames.

There are 180 mm high 180 mm longitudinal chassis legs made of 2 mm thick galvanized sheet metal under the cells. There are eyebolts for crane transportation and blade slots for forklift transportation at the corners of the frame legs.

Cell fans are used in areas where fresh air is required without air conditioning. Our fans have G4 cassette filter as standard. Other filter types can be used upon customer request.