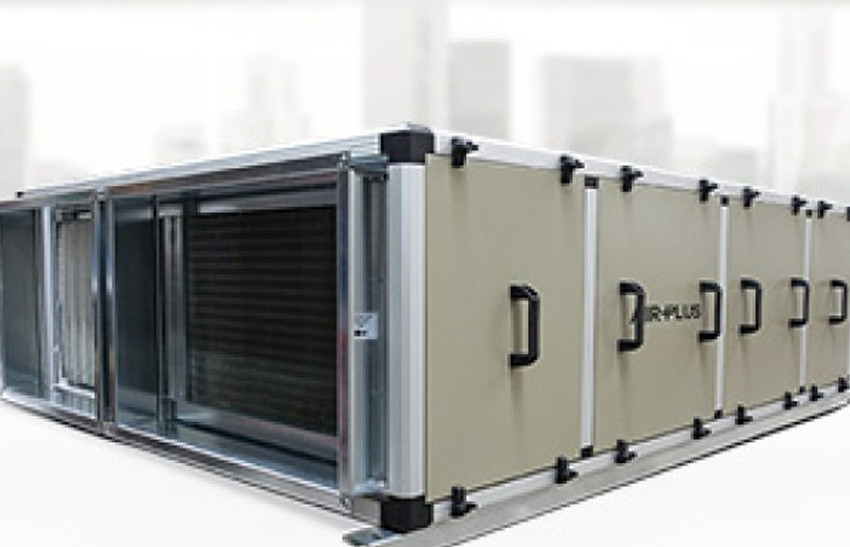

Ceiling type heat pump heat recovery devices are devices that save energy by recovering heat energy without mixing exhaust air and fresh air with the help of fans inside, thanks to the plate exchanger designed to meet the exhaust and fresh air needs in closed spaces. Ceiling type heat pump heat recovery devices are compact devices designed to provide high indoor air quality as well as energy saving.

In addition to the energy saving advantage, they also meet the need for air-conditioned fresh air in workplaces, banks, offices, hotels, homes, cinemas, fair-exhibition areas, hospitals, multi-purpose halls, restaurants, coffee houses and such places where high density exhaust is required. The system operates in heating or cooling mode according to the season selection made from the control panel. The device has an automatic free-cooling feature and thanks to this feature, it allows more savings in operating expenses.

It is produced in 3 standard models with an air flow rate range of 1000 m³/h - 3000 m³/h. The models produced are designed to be placed in a suspended ceiling and to be easily installed and maintained. The device has a compact structure with the evaporator, condenser, compressor, heating-cooling equipment and control panel inside.

The Control Unit is capable of controlling the basic equipment and optional accessories in the Heat Pump Heat Recovery Device. The frame of the ceiling type heat pump heat recovery device is manufactured from natural anodized aluminum profile and plastic corner elements. The cell panels are 42 mm thick stone wool, the outer wall is electrostatic powder painted, and the inner wall is manufactured from galvanized sheet metal. It has self-motorized, imported, silent, single-phase (230 V) and plug fans suitable for speed control. Aluminum plate heat exchangers with 40-50% efficiency are used in our heat recovery devices. High-efficiency, scroll compressors are used in Heat Pump Heat Recovery devices. The safety of the system is ensured with low and high pressure pressure switches. Copper tube - aluminum fin type high efficiency evaporator and condenser are used. Distributor is used for homogeneous refrigerant distribution at the evaporator inlet. Since air velocities in the evaporator and condenser are selected as 2.5 m/s or lower, air side pressure losses are reduced. There is a condensation pan made of stainless steel under the evaporator and condenser. After the fresh air in the devices is cleaned from particles in the outside and space air with G2 class filters in the exhaust line, it is passed through the plate heat recovery exchanger. Thus, the air blowing into the space is cleaned from particles and the plate heat recovery is purified from dirt.

The products of AIRPLUS AIR CONDITIONING TECHNOLOGIES, which has been producing and providing service with 100% Turkish Capital in the air conditioning sector for 11 years, have been used in many countries with different climates as well as in Turkey for years.

AIRPLUS’s product range is quite wide enough to cover all HVAC projects: Air Handling Unit (with automatic control panel upon customer request / special design as required), DX Coil Air Handling Unit (with automatic control panel / special design as required), Roof Type Package Air Handling Unit (Rooftop), Hygienic Type Package Air Handling Unit, Concealed Floor Type Fan Coil Unit, Indoor Swimming Pool Dehumidification Unit, Hood Unit (with Electrostatic Filter), Ceiling Type Heat Pump Heat Recovery Unit, Ceiling Type Heat Recovery Unit, DX Coil Ceiling Type Heat Recovery Unit, Cell Aspirator, Fan, Hot Air Unit (with Axial / Radial Fan), Floor Convector, Shaft Damper, Shelter Fan, Rectangular Duct Type Fan, Duct Type Electric Heater, HEPA Filter Box. AIRPLUS carries out its production with its qualified personnel in its facility in Çekmeköy, Istanbul, and attracts attention with its initial investment cost, equipment and workmanship quality, energy efficiency, flexible solution alternatives suitable for the project, suitable delivery times and original design.